How to Troubleshoot Pallet Scales and Other Floor Scales

If you work with floor scales in your business, it may be important for you to know when it’s time to calibrate a pallet scale and other types of floor scales. Once you determine your scale needs calibration, adjustment, repair or any services, you can reach out to a qualified professional at Precision Solutions for troubleshooting assistance or a repair job. We apply standards traceable to the SI through NIST, using an unbroken chain of calibrations. Contact Us Today!

Floor Scale Repair, Adjustment and Calibration Procedure

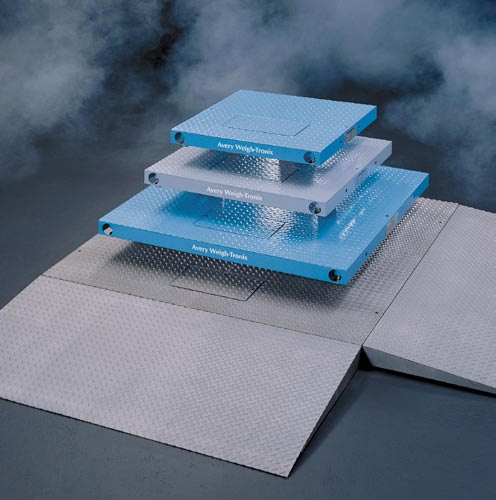

First of all, you want to make sure you are starting with a high-quality pallet scale that functions properly. If your scale is of poor quality, or not the right fit for your weighing application, even if you properly calibrate it, it will quickly drift and you will end up with inaccurate measurements and having to repeatedly adjust and recalibrate the scale.

The first step is to make sure you actually need to calibrate your floor scale.

Indicators that you may need service, repair or adjustment for your floor scale:

1. Not Reading Weight:

If you have weight on the scale but it is giving a reading of zero, you may need to adjust or repair the scale. Some ways to troubleshoot this issue are:

- Make sure all the supports of the scale are in direct and solid contact with the floor and that the scale is level.

- Make sure you have removed all the shipping screws from the platform.

- Make sure the feet are screwed in properly and not screwed in too high where a stud may be blocking the load sensor from flexing.

2. Reading Fluctuates:

You have weight on the scale, but the reading never settles down to a consistent number, jumping back and forth. If you experience this issue, your scale most likely needs service, repair or adjustment. Professionals can help you determine the issue and decide whether the scale needs calibration once it works properly again. Some ways to troubleshoot this problem are:

- Make sure the scale is not on a vibrating surface or being buffeted by winds.

- Make sure the scale is plugged in with a clean power source.

- Make sure any devices that might cause RF interference, like two-way radios or heavy industrial electric motors, are not interfering with the scale.

- Make sure no pins are missing from the load cell cable.

3. Different Areas of the Platform Produce Different Readings:

Depending on where you place the weight, you get a different measurement.

- Make sure you did not screw in one of the feet so tightly that it prevents the load sensor from flexing.

- Make sure all feet are on the floor.

- Make sure nothing is interfering with the platform.

Professional Floor Scale Calibration, Adjustment and Service in Eastern PA and New Jersey

If you have any of the above problems and the troubleshooting steps do not work, it might be time to discuss the issue with a professional like Precision Solutions. Our experienced technicians will make a site visit and help you reliably troubleshoot and determine the issue. For over 50 years, we’ve provided quality calibration services on-site, as well as maintenance, repairs, adjustments and other services as needed. We proudly meet the calibration needs of companies with scales all over Eastern PA and New Jersey.

We work with all manner of scales in a broad range of industries, from healthcare and warehousing to meat processing and more. You will get an accurately calibrated scale that you can rely on every time. We are an accredited ISO 17025 calibration company that adheres to the highest standards of quality when it comes to calibration, so you know we are a name you can rely on and trust to calibrate your scales accurately and efficiently as well as provide calibration certification and weight traceability.

To learn more or for a free quote on calibration services, just give us a call at 215-536-4400 or contact us online today. We look forward to helping you with all your floor scale, pallet scale and other scale calibration needs.